Tem No: zh-mb004 Capacity: 250ml 350ml 400ml 500ml 1000ml Material: PET Shape: round Used for: shampoo packaging Place of origin: Shenzhen, China MOQ: 5,000 pieces Unit price range: $0.3-0.6 Sample: available, free, client pay for sample shipping cost

Tem No: ZH-C70244 Capacity: 1L Material: 500ml 2L 4L Used for: detergent liquid bottle Place of origin: Shenzhen, China MOQ: 5,000 pieces Unit price range: $0.32-$0.48 Sample: available, free, client pay for sample shipping cost

Tem No: zh-p9309 Capacity: 2L Material: HDPE Shape: Round Used for: detergant liquid Place of origin: Shenzhen, China MOQ: 5,000 pieces Unit price range: $0.32-$0.48 Sample: available, free, client pay for sample shipping cost

Tem No: zh-c70231 Capacity: 1L Material: HDPE Shape: Round Used for: detergant liquid Place of origin: Shenzhen, China MOQ: 5,000 pieces Unit price range: $0.32-$0.48 Sample: available, free, client pay for sample shipping cost

Ÿ Production increased by 30%

Ÿ Blow molding machine energy consumption reduced by 60%

Ÿ Saving the cost of installing additional blow molding machines to upgrade power supply from 600kVA to 800 kVA $ 356,000

Ÿ Saving the cost of refurbishing the pump and drive using the same technology $ 44,000

Ÿ The synchronous reluctance motor operates quieter than the standard AC motor and improves the working environment

PrimePac in Northern Ireland was in a dilemma when the old blow molding machine operating for 23 years was reduce output. This machine uses a hydraulic motor to power the extruder in the blow molding machine. It runs 24 hours per day, five days per week, this motor has been running very inefficiently, and poorly speed control.

PrimePac decided to replace the old hydraulic motor that drives the extruder inside the blow molding machine because it was inefficient and the speed control was unstable. The new solution uses ABB synchronous reluctance motor and ACS880 inverter.

Previously, PrimePac produced a plastic bottle in just 10 seconds. In recent years, the unit production time extended to 12 seconds. Extruder to produce with the "long tail" of the excess plastic, but also to its dressing and recovery, the entire process of energy consumption is huge.

PrimePac had planned to spend $ 44,000 on refurbished machines. Although this allows the machine to continue to run, but it is still used in the original technology, energy consumption remains the same. And energy consumption is a key factor for this facility with a capacity limit of 600 kVA. The introduction of additional full-electric injection molding machine to produce new bottles of the plan need to add more than 300,000 US dollars investment, investment is mainly used for power supply system upgrades.

Find the possibility through energy assessment

In order to find other solutions, PrimePac invited its energy and automation partner Advantage Control Limited (ABB Authorized Value Supplier) to conduct energy assessments for existing machines.

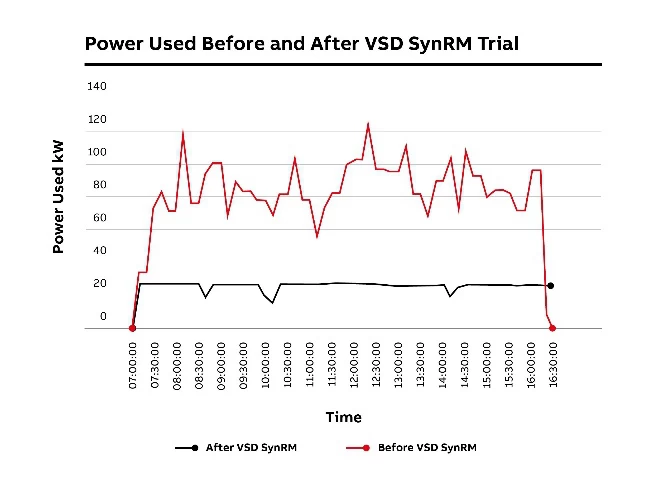

Advantage Control Limited has measured energy consumption in the existing full electric mode for a week. The results of the assessment show that the old machine in the production of the same size and weight of plastic bottles, the energy consumption is huge. And because the hydraulic system needs to consume additional torque at start-up, there is a problem that energy consumption is unstable and power consumption is large.

Even worse, blow molding machine poor speed control function will lead to plastic bottles deformed.

The combination of ABB's synchronous reluctance and ACS880 drives not only reduces power consumption, improves speed control, improves product quality and maintains consistency, but also releases capacitors to power the new blow molding machine.

The ACS880-01 drive has an IP55 degree of protection that can be installed near the production process.

The increase in energy efficiency allows PrimePac to install a new extruder without upgrading the 600 kVA power supply system.

Energy saving

The new motor - drive combination installation is complete, the recorded data show that energy savings rate of 60%. Even if you need to retrofit the machine, the 55 kW IE4 synchronous reluctance motor - drive combination of $ 11,000 purchase cost is expected to be able to recover the investment within 12 months.

Speed regulation is the key to success

ABB industrial drive with direct torque control function (DTC), in the actual speed control of the drive has made substantial progress. Now, it is more accurate, so that through the extruder and into the cavity of the plastic length, weight consistent. This means that the product is no longer spilled, no longer "long tail", waste is also reduced.

Increased production

Previously, only 63% of the extruded semi-finished products were really made of plastic bottles. This is because the machine movement is unstable and intermittent. Synchronous reluctance motor - drive combination After installation, 96% of the extruded semi-finished products have been successfully made into plastic bottles. Another 4% is due to the gradual downtime.

With the reduction of waste, the frequency of 18.5 kW granulator used for waste recycling has also been reduced, which can save 5% of the energy consumption.

Other advantages include, significantly reducing noise and vibration, and now the operator is standing next to the motor to hear the conversation.

Exceed customer expectations

Primephac Ltd Engineering Manager Clifford Craig said:

"We were unable to install the new machine because of the lack of power, and now the old blow molding machine's energy consumption is reduced by 60%, enough to allow us to install another new all-electric blow molding machine. This is completely beyond our expectations. With a ABB synchronous reluctance motor - drive combination, our production is significantly increased. "

We are a China plastic bottle manufacturer, specializes in all kinds of plastic bottles, containers and cans of continuous extrusion blow molding, with several production machines, in this area a profound understanding of the importance of a good machine.

For more information please visit:

http://new.abb.com/drives/segments/plastics-and-rubber/case-primepac